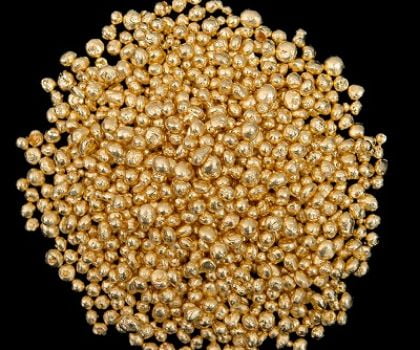

Evaporation materials

Deposition-based thin-film formation depends on the

evaporation performance of evaporation material.

Our precious metal evaporation materials have excellent

evaporation characteristics.

- We use high-purity base metals derived from precious metal refining technologies that we've accumulated over many years of operations.

- We can manufacture both single-metal and alloy-composition products.

- Our MNS® grade evaporation materials for use in precision vapor deposition applications (such as lift-off) can be relied upon to deliver yield improvements.

- They can improve material utilization ratios and shorten soak (dissolution) times when forming electrodes on bottom surface of discrete semiconductors such as power semiconductors.

- Starter material manufacturing improves material utilization ratios.

- Products are available in a range of types (wire, pellets, granules, blocks, etc.).

- We can also accommodate requests to process small quantities for prototyping or testing purposes.

Product Information

Pure metal Evaporation materials

| Metal | Purity | Type | Principal applications | |||||

|---|---|---|---|---|---|---|---|---|

| Communications ICs | Laser elements | LEDs | Power semiconductors | SAW devices | Crystal devices | |||

| Au | 4N 5N | Granular, wire, slugs, pellets | ○ | ○ | ○ | ○ | ○ | ○ |

| Ag | 4N | Granular, wire, slugs, pellets | - | - | - | ○ | - | ○ |

| Pt | 3N5 | Wire, slugs, pellets | ○ | ○ | ○ | - | ○ | - |

| Pd | 3N5 | Wire, slugs, pellets | ○ | - | - | - | ○ | - |

We can also fabricate starter sources in custom types.

Eutectic alloy Evaporation materials

| Metal | Purity | Type | Principal applications | |||||

|---|---|---|---|---|---|---|---|---|

| Communications ICs | Laser elements | LEDs | Power semiconductors | SAW devices | Crystal devices | |||

| AuGe | Ge12% | Splatter, slugs | - | ○ | ○ | - | - | - |

| AuSn | Sn20% | slugs | ○ | ○ | ○ | - | - | - |

Inside chamber life cycle management

In the area of precious metal film formation, recovering material deposits inside equipment is the first step towards lowering costs. For this service, sales engineers with specialized precious metal skills provide comprehensive management of the precious metal life cycle inside vacuum thin-film formation systems.

Precision cleaning of parts inside equipment

We recover precious metals that have built up on parts, restore the parts by cleaning them to a high level of purity, and reuse the recovered precious metals as raw materials for targets.

Recovery and refining of used targets

We recover old parts whose sputtering service life has been exceeded and reuse refined precious metals as raw materials for targets.

- We manage the precious metals recycled from precision cleaning and used targets in customers’ accounts to realize efficient use.

- We can propose a variety of base metal use arrangements to lower both initial and running costs associated with target use.

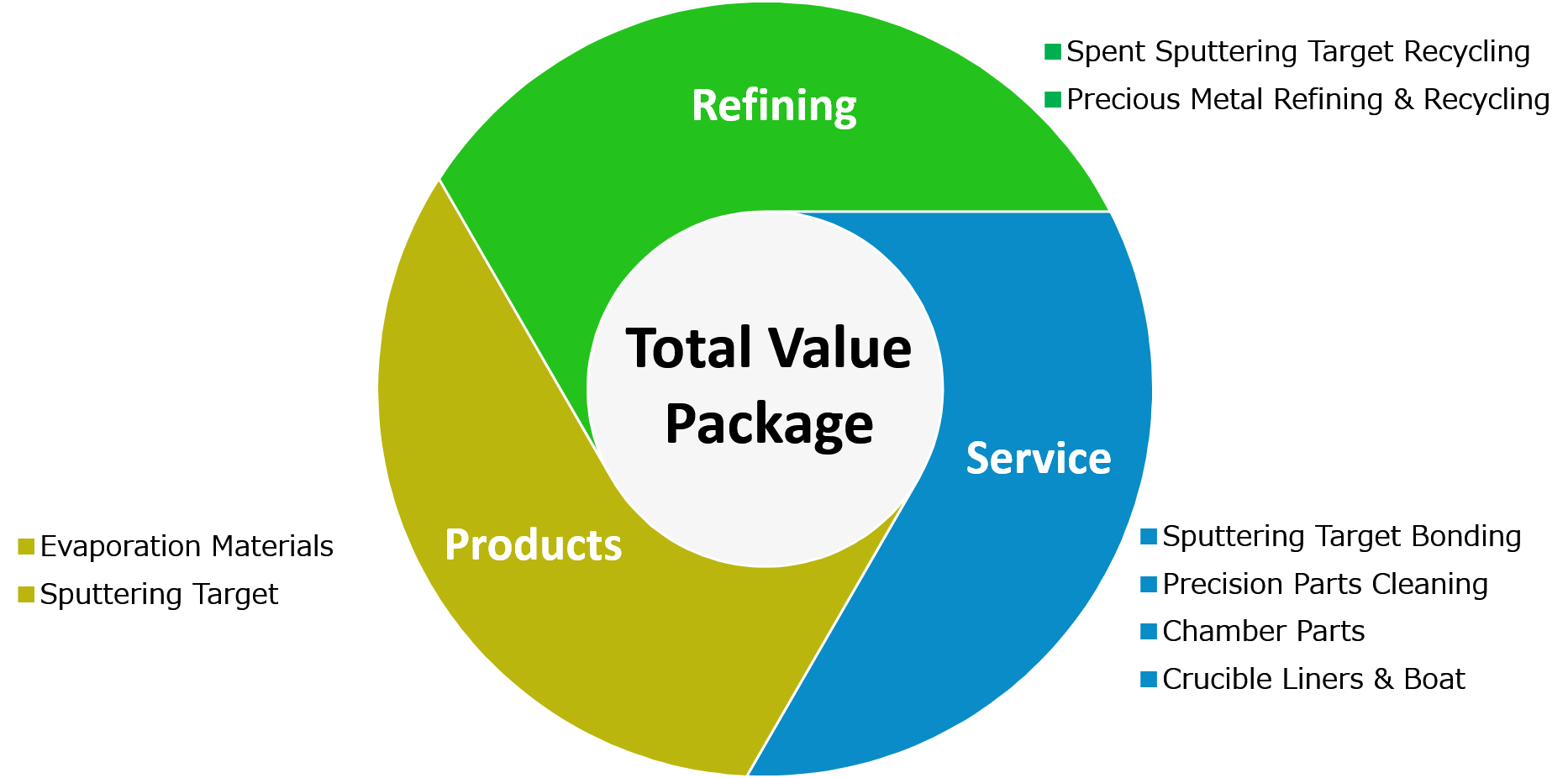

Providing three types of vacuum film formation system value

in a single package