Characteristics of

Our Precious Metal Business

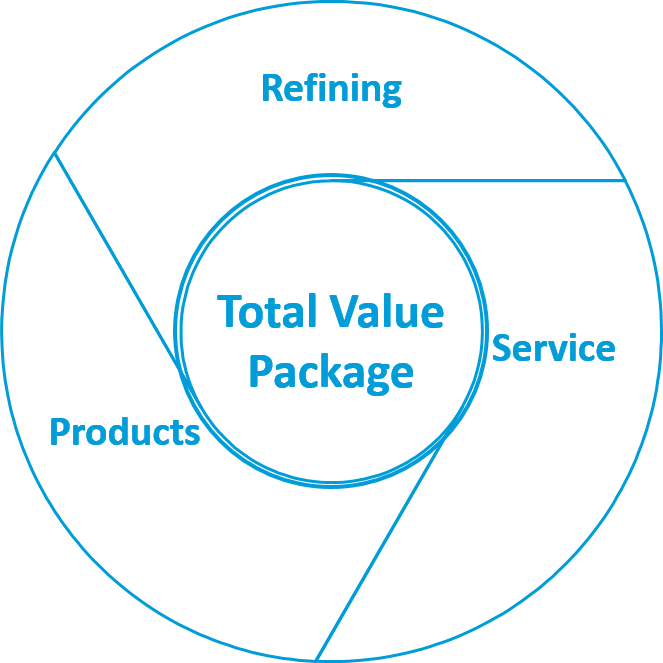

Through our long-running, advanced precious metal refining technology and associated precious metal chemical products and processed products

and services, we provide precious metal life cycle management,

a proprietary closed-loop solution that reduces environmental impacts.

Value

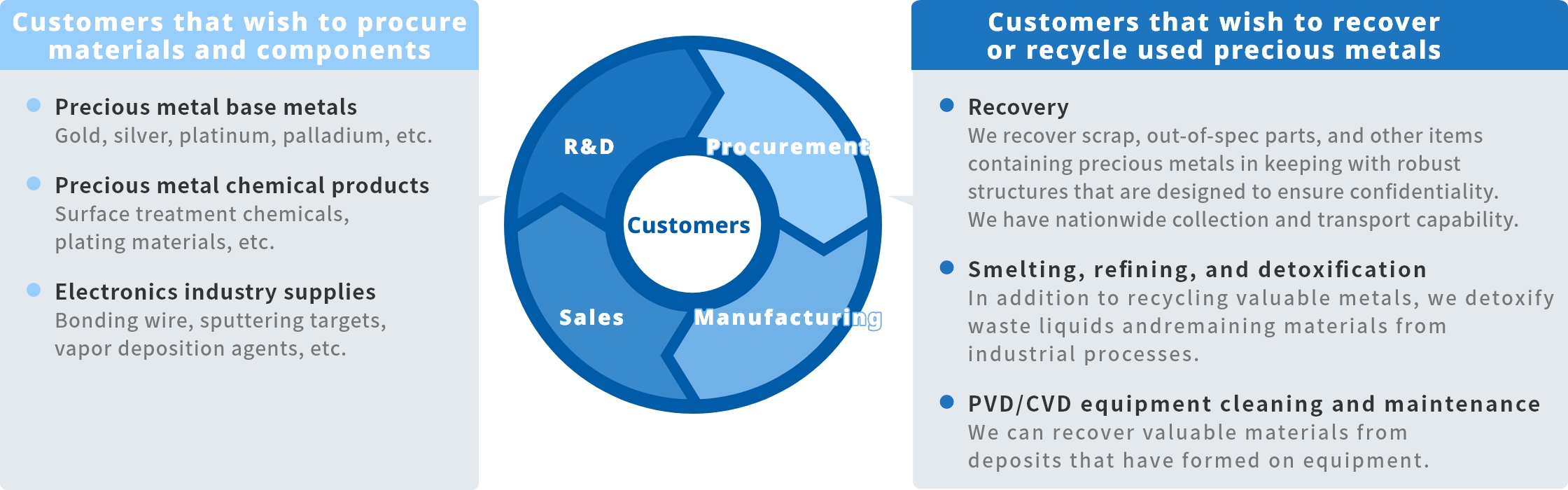

Our Precious Metal Business provides comprehensive support for resource circulation, from precious metal smelting and refining to sale and recycling.

Our precious metal base metals, which are created by advanced smelting and analysis technologies, boast quality that is backed up by certification in Japan and overseas. From the perspective of reducing CO2 emissions, we also can supply closed-loop gold, which is attracting attention from businesses worldwide.

Precious metals are limited resources. In fields where use of precious metals is unavoidable, for example electronics, developing mechanisms for recycling through R&D, procurement, manufacturing, and sales is an essential part of being able to realize sustained growth. As a company that has put in place one-stop structures that allow it to offer services ranging from the manufacture and sale of precious metal chemical products and processed products to the recycling of scrap and other waste streams, we’re helping build resource recycling mechanisms for precious metals.

Four strengths of our Precious Metal Business

Status as a globally

recognized refiner of precious metals

- Certified by the Tokyo Commodity Exchange and London markets (LBMA, LPPM)

- Advanced precious metal smelting, refining, and analysis technologies

- Ability to supply closed-loop gold, which is attracting attention worldwide

We've built an integrated series of production structures that extends from pre-treatment to smelting and refining based on more than 70 years of expertise in precious metal refining. We perform sampling at each process and use high-precision analysis technologies in content assessment and quality control.

The highly stable precious metal base metals produced by these structures are recognized as Good Delivery-compliant. Four of our products–gold, silver, platinum, and palladium–have been designated as having sufficient quality to be delivered in fulfillment of contracts by the Osaka Exchange(OSE), which has also certified our appraisal services.

We've registered our brand with the London Bullion Market Association (LBMA) and the London Platinum and Palladium Market (LPPM), which recognize the high quality of our base metals.

In recent years, use of recycled metals has been attracting worldwide attention from the standpoint of reducing CO2 emissions. We're able to supply Green Gold, which has a smaller environmental footprint, and going forward, we’ll continue to contribute to the green procurement field, an area where demand will continue to grow.

Chemical technologies that help create high-quality precious metal chemical products

- Chemical plant technologies and track record gained through the smelting and refining of precious metals

- Provision of high-purity, high-stability plating chemicals and precious metal chemical products

- Broad post-purchase support, from liquid management to liquid analysis and defect countermeasures

Our strengths stretch back about 70 years, when our business was founded to refine silver from photographic-use photosensitive materials that were no longer needed. We gained extensive expertise in the field of precious metal chemical technology through smelting and refining processes for precious metals.

We take advantage of these technologies in the precious metal chemicals field to provide a broad range of surface treatment chemicals and materials that play an essential role in electronic component and semiconductor manufacturing. We also offer an extensive line of precious metal chemical products for applications such as plating chemicals and catalyst raw materials.

In addition, we provide comprehensive support following customers’ purchases of plating liquid, from liquid management to liquid analysis and defect countermeasures. We’re also meeting advanced demand for precious metal chemical products by strengthening our in-house R&D structures.

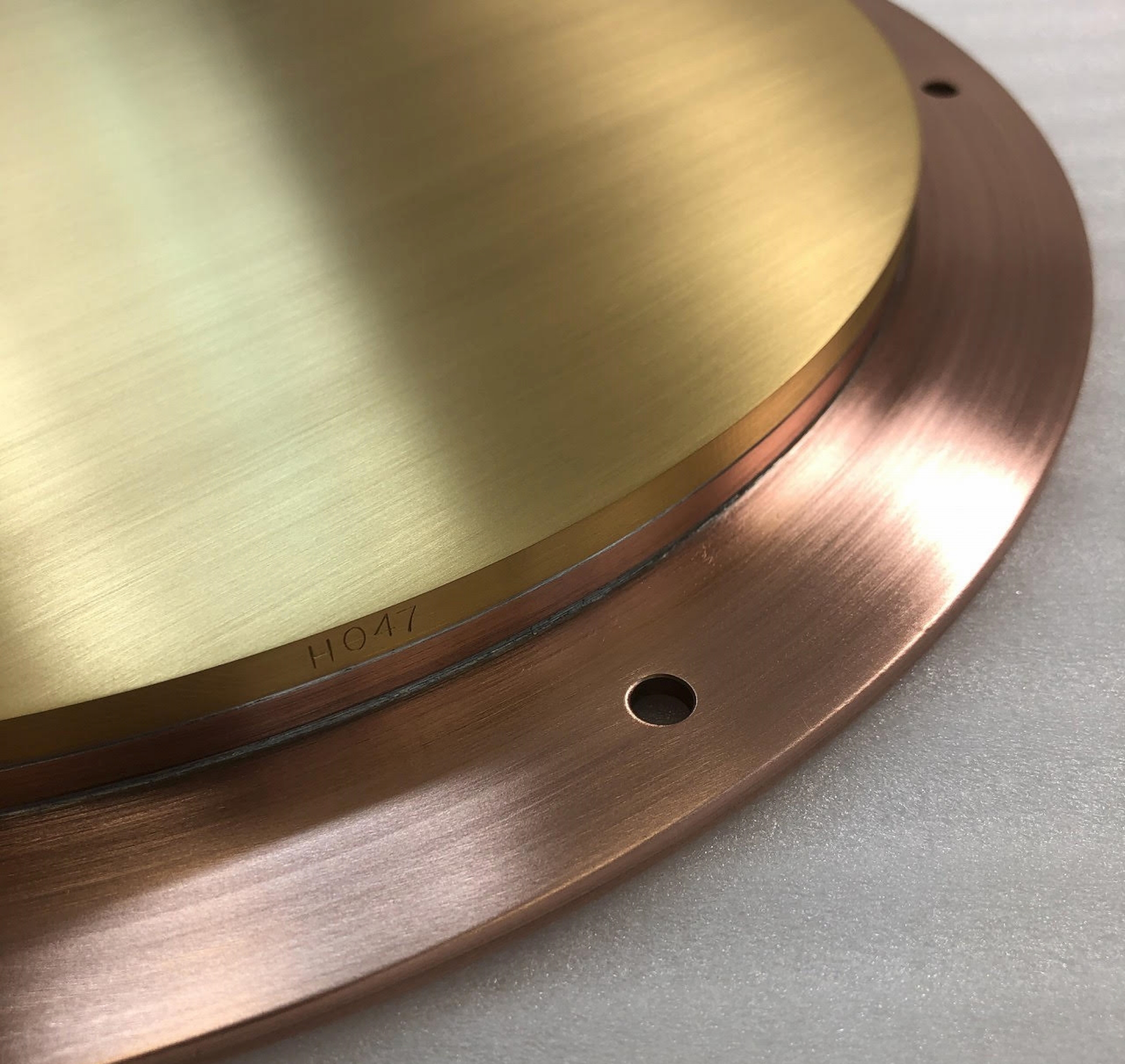

Precious metal materials to fulfill batch order demand for major materials in the semiconductor and electronic component fields

- High-purity, advanced-function precious metal products for use in wiring and electrode formation

- Part cleaning service that includes recovery and refining of precious metal deposits on internal fixtures such as shield kits in film formation systems

- Processing of vapor deposition source peripheral parts and shield kits, including film formation systems components and crucible liners

We supply high-purity, advanced-function precious metal processed products for use in the manufacture of semiconductors and electronic components. These offerings include sputtering targets, vapor deposition materials, and other vacuum thin-film materials as well as packaging materials such as bonding wire. Our integrated approach to product development, manufacturing, and sales allows us to meet the full range of customer needs, from improving cost performance to developing materials that provide the required characteristics. In addition, we provide precision cleaning service to restore internal parts such as shield kits in vacuum film formation systems to a clean state by recovering, refining, and cleaning precious metals. This service further contributes to the effective use of resources through the recycling of minuscule quantities of precious metals contained in material deposits that form on fixtures and by extending the service life of those fixtures through precision cleaning.

Recovery and refining of precious metals by means of safe, secure, and highly reliable structures

- Refining and analysis technologies that are recognized by markets with global authority

- Robust security structures that prevent leaks of confidential information

- Thoroughgoing dedication to appropriate treatment in all processes, including detoxification and recycling

As a company that collects, treats, and recycles electronic component scrap and out-of-spec parts, we’ve put in place security structures to prevent the outflow of confidential information from semiconductors, electronic components, and other parts that aggregate customers’ advanced technologies.

We can accommodate requests for customer-attended crushing on the premises of customers’ plants using a mobile crusher vehicle that we developed, as well as customer-attended treatment at our own treatment facilities. In addition to 24-hour security and monitoring structures at our facilities, we keep confidential information from being removed from our sites by means of an access control regime that employs X-ray metal detectors.

We can also work with our waste collection, transport, and treatment division, which operates another of our flagship businesses, to provide comprehensive coordination for customers’ resource circulation. Our waste collection, transport, and treatment service has secured collection and transport permits for industrial waste and specially controlled industrial waste in all 47 of Japan's prefectures. In addition to thorough waste recycling and detoxification at our treatment facilities, we can accommodate requests for appropriate treatment of a broad range of waste in partnership with a nationwide network of trustworthy affiliates.