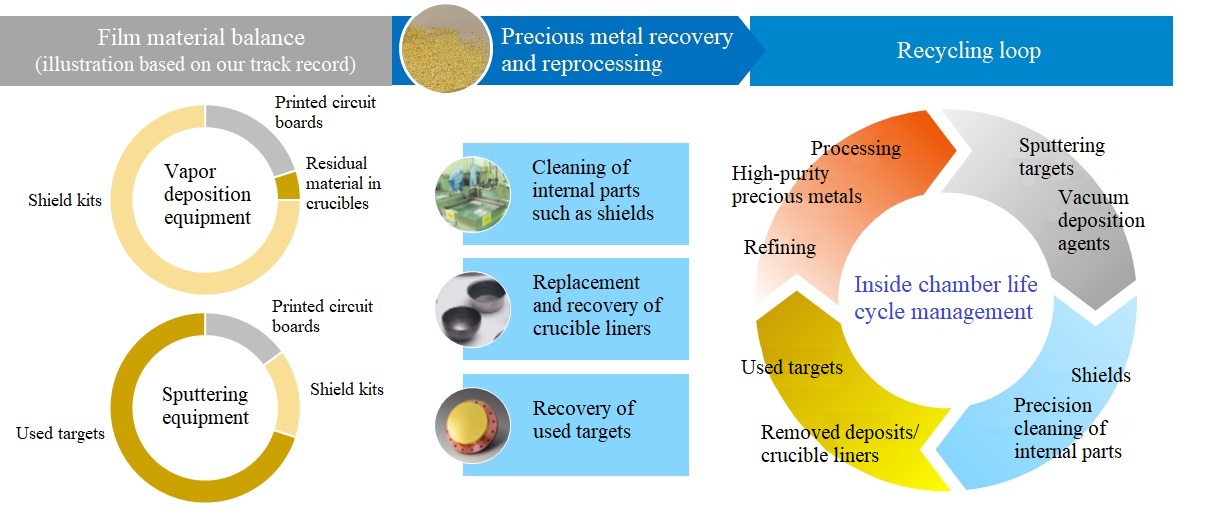

Inside chamber life cycle management

We provide three types of vacuum film formation system

value in a single package.

Comprehensive solutions for vacuum equipment

Comprehensive range of capabilities that extends from sales of vacuum film formation materials, which is our primary service, to related businesses.

We take a cyclical, problem-solving approach to precious metal life cycle management with the goal of realizing efficient use of precious metal resources.

As one of the first companies in the industry to commercialize cleaning of vacuum film formation system parts in order to recover precious metals, we set the standard for precision cleaning.

Overview of inside chamber life cycle management

Drawing on more than 70 years of experience in precious metal recovery, refining, and recycling, we offer packaged solutions that can be customized to satisfy customers’ needs. Our specialized engineering service team can propose solutions that align with customer requirements. Specialized engineering teams at our plant continuously search for the best possible recovery, refining, and cleaning methods.

Inside chamber life cycle management makes it possible to recover, refine, and recycle precious metals from byproducts generated by the following thin-film deposition processes.

- Material removed from shields and other equipment by the customer

- Wafer, printed circuit board, and evaporation material scrap

- Used evaporation crucibles

- Used sputtering targets, regardless of supplier

Click here to contact us concerning inside chamber life cycle management.

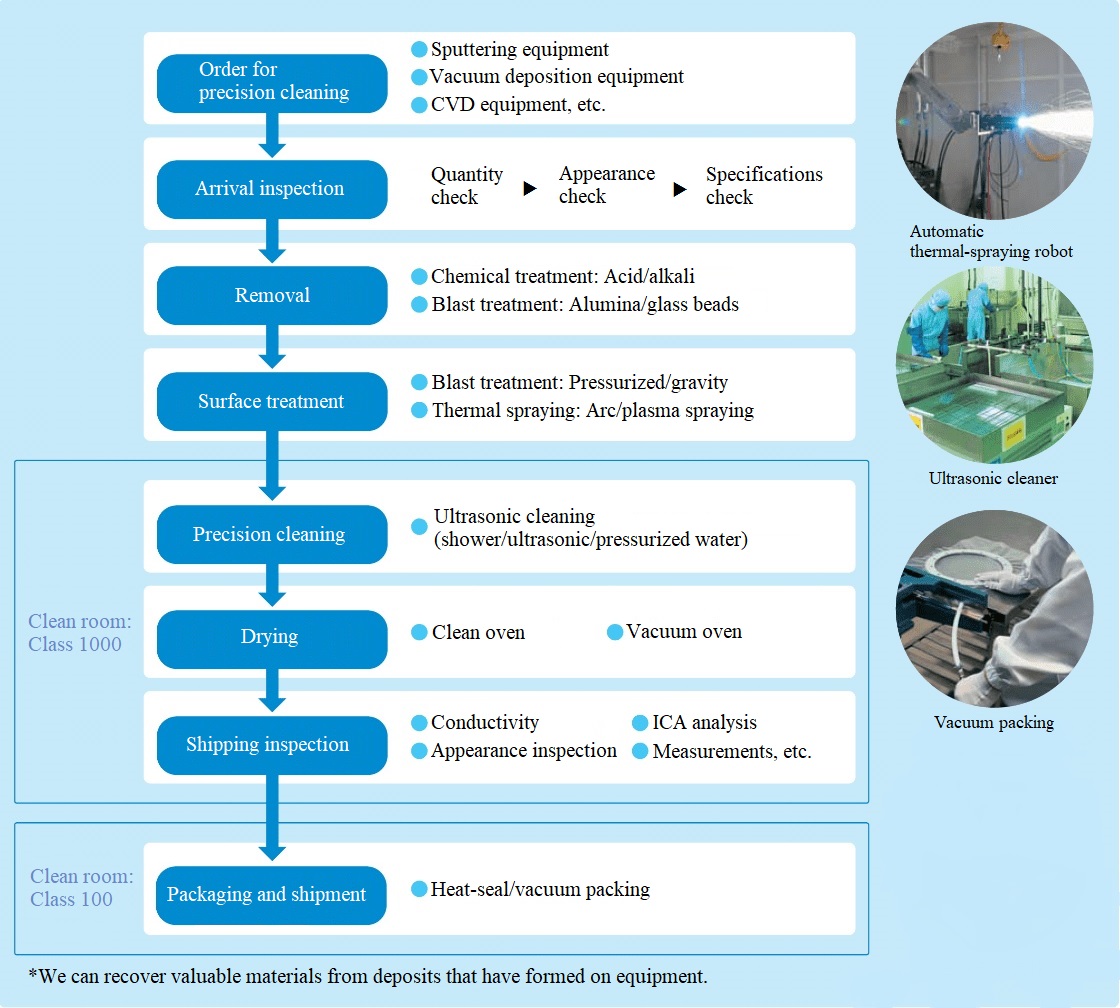

Characteristics of precision cleaning of vacuum system parts

We’ve led the industry by fielding proprietary deposit separation and cleaning technologies derived from our precious metal refining technology. By extending the service life of shield kits and other parts inside vacuum chambers, this business has pioneered new ways to improve production performance and ensure effective use of precious metal resources. We’re proud to provide this service as a comprehensive inside chamber life cycle solution.

Advanced cleaning technology and service, offered through two plants in Japan and three plants elsewhere in Asia.

We satisfy customers’ vacuum system internal part recycling and cleaning requirements with innovative cleaning technology and precious metal smelting technology, an area in which we have an extensive track record.

- Certified by major semiconductor equipment manufacturers worldwide to perform initial cleaning of genuine parts

- Ultrasonic cleaning with super-pure water with a specific resistance of at least 17 MΩ inside a Class 1,000 clean room

- Management that keeps processes separate in order to prevent copper contamination

- Full complement of analytical equipment

Services by process

Advanced cleaning technology and service

We satisfy customers’ internal chamber part recycling requirements with innovative cleaning technology.

- Collaboration with major semiconductor equipment manufacturers worldwide (which have certified our plants to perform initial cleaning of certain genuine parts)

- Degreasing and cleaning capability when necessitated by post-processing conditions (alcohol or acid/alkali)

- Precision cleaning inside a clean room (ultrasonic cleaning using super-pure water with a specific resistance of at least 17.0 MΩ)

- Class 1,000 and Class 100 clean rooms

- Prevention of copper contamination (by keeping copper and non-copper lines separate)

- Contamination and particle countermeasures (ability to propose pressurized water cleaning; availability of analytical equipment)

Cleaning for reuse (removal of deposits in sputter equipment and vapor deposition equipment)

We have an extensive track record of cleaning for reuse in partnership with a variety of device manufacturers, particularly for metal films.

Precision cleaning process for vacuum film formation system parts

*We can propose optimal process conditions in order to limit film peeling and particle shedding by effectively combining anchoring and cushioning effects.

Thermal spraying evaluation options include roughness measurement using a surface tester, surface and cross-sectional coating observation using a macro lens or SEM, and adhesion evaluation using a tensile tester.